Introduction

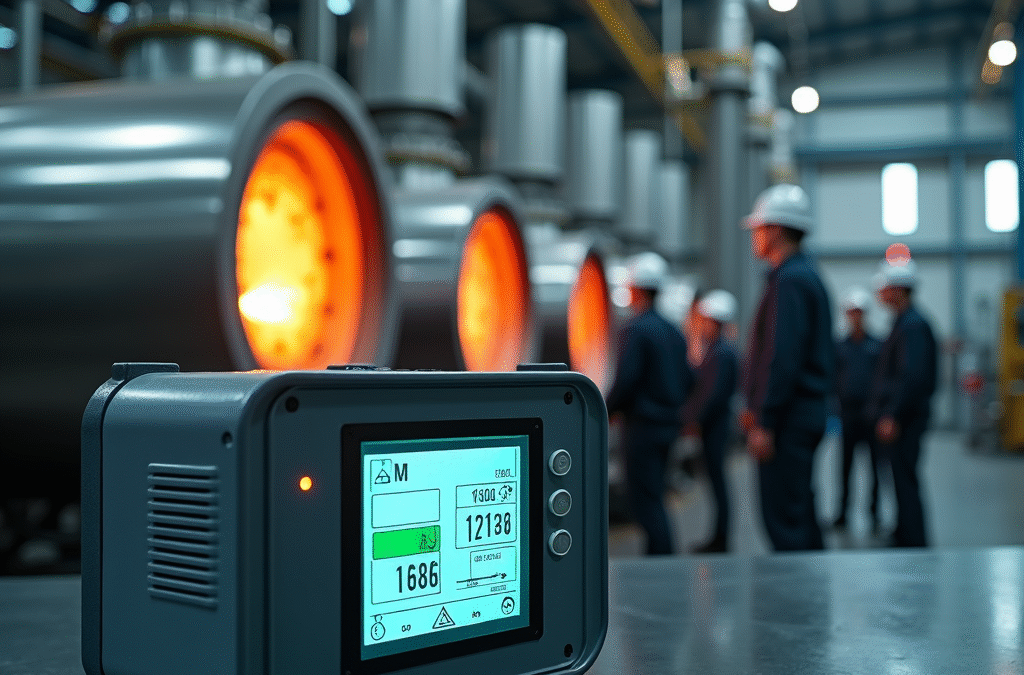

In today’s industrial landscape, energy efficiency and cost optimization are critical for maintaining competitiveness and sustainability. For industries relying on combustion processes—such as power plants, refineries, cement kilns, and boilers—precise control of oxygen levels is a game-changer. An Oxygen Analyzer is a powerful tool that helps industries achieve optimal combustion efficiency, reduce fuel consumption, and minimize emissions.

At Advance Engineers, we specialize in Field Instrumentation and Process Automation, empowering industries in Energy, Efficiency, and Automation. Our expertise helps clients across sectors cut costs, enhance productivity, and meet environmental regulations—all while maximizing operational efficiency.

In this blog, we’ll explore:

- The role of oxygen analyzers in combustion processes

- How they drive fuel savings and operational efficiency

- Their impact on emissions reduction and compliance

- Real-world benefits for industries

Let’s dive in!

![[Artistly Design] 01992d57-6f83-7241-b9da-cfe58b91bb01 Oxygen Analyser](https://advance-engineers.com/wp-content/uploads/2025/09/Artistly-Design-01992d57-6f83-7241-b9da-cfe58b91bb01.png)

Why Oxygen Levels Matter in Combustion

Combustion is a chemical reaction between fuel and oxygen, producing heat and byproducts like CO₂, water vapor, and, if inefficient, harmful pollutants like CO, NOx, and soot. The air-fuel ratio determines combustion efficiency:

- Too much oxygen (excess air): Wastes energy by heating unnecessary air, increasing fuel consumption.

- Too little oxygen (incomplete combustion): Leads to unburned fuel, soot formation, and higher emissions.

An Oxygen Analyzer provides real-time, accurate measurements of oxygen levels in flue gases, allowing precise control of the combustion process.

How Oxygen Analyzers Drive Cost Savings

1. Fuel Efficiency & Cost Reduction

- Optimal air-fuel ratio: Oxygen analyzers help maintain the ideal stoichiometric ratio, ensuring complete combustion with minimal excess air.

- Reduced fuel consumption: Even a 1% reduction in excess air can lead to 1-2% fuel savings—a significant cost reduction for large-scale operations.

- ROI within months: Many industries recover the cost of oxygen analyzers within 6-12 months through fuel savings alone.

2. Lower Maintenance & Operational Costs

- Prevents soot and corrosion: Incomplete combustion leads to soot buildup in boilers and heat exchangers, increasing maintenance costs. Oxygen analyzers help minimize these issues.

- Extends equipment lifespan: By reducing thermal stress and corrosion, analyzers help prolong the life of burners, boilers, and furnaces.

3. Emissions Compliance & Sustainability

- Reduces NOx, CO, and particulate emissions: Regulatory bodies worldwide impose strict emissions limits. Oxygen analyzers help industries stay compliant while avoiding fines.

- Supports ESG goals: Companies committed to sustainability can reduce their carbon footprint by optimizing combustion efficiency.

Why Choose Advance Engineers?

At Advance Engineers, we don’t just supply instruments—we deliver tailored solutions for energy efficiency and process automation. Our expertise includes:

✅ Cutting-edge oxygen analyzers from leading global brands ✅ Customized integration with your existing control systems ✅ Expert support for installation, calibration, and maintenance ✅ Proven track record in helping industries save millions in fuel costs

We work closely with clients in Energy, Efficiency, and Automation, ensuring that every solution aligns with their operational and sustainability goals.

![[Artistly Design] 01992d59-7862-73d8-8a51-a7fe4b1c3091 emissions](https://advance-engineers.com/wp-content/uploads/2025/09/Artistly-Design-01992d59-7862-73d8-8a51-a7fe4b1c3091.png)

If you’re looking to cut fuel costs, improve efficiency, and reduce emissions, an Oxygen Analyzer is a smart investment. At Advance Engineers, we’re here to help you maximize savings and operational excellence.

📞 WhatsApp us: +91 8427001018

📧 Email us: sales@aecl.in

🌐 Visit us: www.advance-engineers.com

Let’s discuss how we can transform your combustion process—contact us today! 🚀