Introduction: Navigating the “Internet of Things” Jungle

“IoT” is perhaps the most overused buzzword in manufacturing today. For a plant manager in Ludhiana or a process engineer in Baddi, the term often conjures vague images of iPads controlling conveyor belts. But in reality, Industrial IoT (IIoT) is about one specific goal: Data Granularity.

The difference between a standard automation system and an IIoT system is simple.

Standard System: Tells you the motor is running.

IIoT System: Tells you the motor is running at 45°C, vibrating at 3mm/s, and consuming 12.5 Amps.

However, the market is flooded with gadgets ranging from ₹500 Wi-Fi chips to ₹5,00,000 Edge Controllers. How do you select the right architecture?

At Advance Engineers, we believe the selection process shouldn’t start with the “Cloud”; it must start at the “Sensor.” This guide breaks down the selection hierarchy from basic connectivity to high-end enterprise integration.

Level 1: The Foundation – Field Connectivity (Basic to Smart)

Before you can analyze data, you must capture it. The selection of your field devices determines the quality of your data.

The Old Way: Analog (4-20mA) & Digital I/O

What it is: The industry standard for decades. A sensor sends a simple voltage or current signal to the PLC.

Pros: Extremely robust, simple to troubleshoot.

Cons: It is “dumb” communication. If a wire breaks or a lens gets dirty, the signal just drops to zero. You get data, but no diagnostics.

When to select: For simple, non-critical status checks (e.g., tank level, door open/close) where advanced analytics aren’t needed.

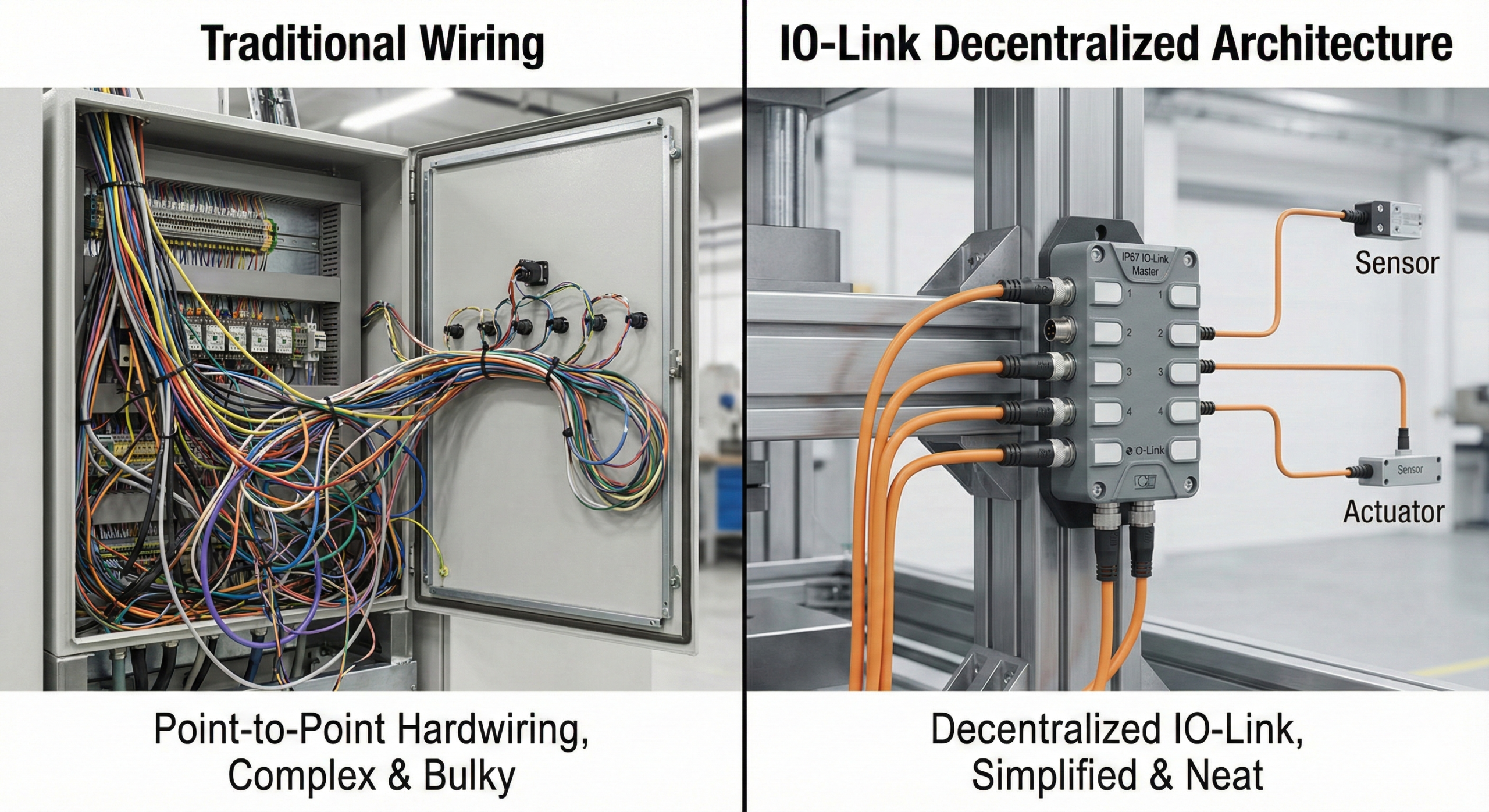

The Upgrade: IO-Link (The “USB” of Automation)

What it is: A point-to-point communication protocol that uses the same standard 3-wire cables but transmits digital data packets.

Why select it: This is the entry point for IIoT. An IO-Link photo-eye doesn’t just tell you “Object Detected”; it tells you “Signal Strength Weak (Lens Dirty)” or “Sensor Overheating.”

Advance Engineers Recommendation: For any new machine build, specify IO-Link masters. It minimizes cabling costs and maximizes diagnostic visibility without needing a high-end IT infrastructure.

Level 2: The Gateway – Getting Data Out of the Machine

Once the data is in the PLC or local sensor network, how do we move it? This is where the “Communication” layer comes in.

Basic: Serial to Ethernet Gateways

Technology: Modbus RTU (RS485) to Modbus TCP.

Application: Ideal for retrofitting older energy meters or VFDs that only speak serial languages.

Selection Criteria: Choose this if you are budget-constrained and simply need to log basic parameters (like Energy kWh) once every minute.

Mid-Range: Protocol Converters (The “Translator”)

Technology: Converting Profinet/EthernetIP to a neutral format.

Application: Your machine runs on Siemens (Profinet), but your upper-level software speaks Allen Bradley (Ethernet/IP).

Selection Criteria: Essential for mixed-vendor plants. Look for gateways that support OPC UA, as this creates a secure, standardized bridge for data.

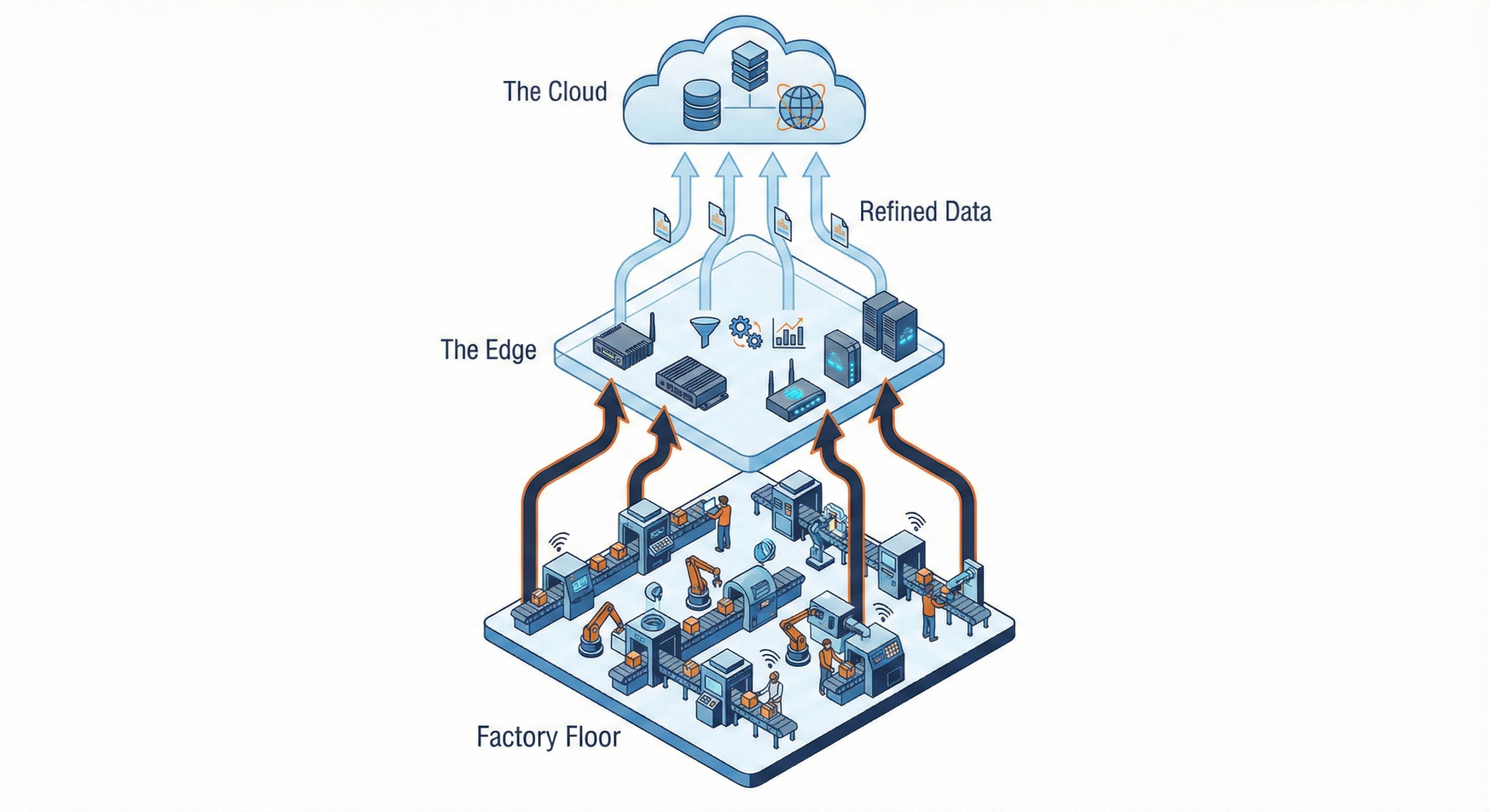

High-End: Edge Controllers

Technology: Industrial PCs (IPCs) or Linux-based Controllers (e.g., Raspberry Pi Compute Module Industrial versions, Siemens Industrial Edge).

Application: Running logic and data processing simultaneously.

Why select it: If you need to process data before sending it (e.g., analyzing vibration capabilities at 10,000 Hz to detect bearing failure), a simple gateway will crash. You need an Edge Controller to “crunch” the numbers locally and only send the result (“Bearing OK”) to the server.

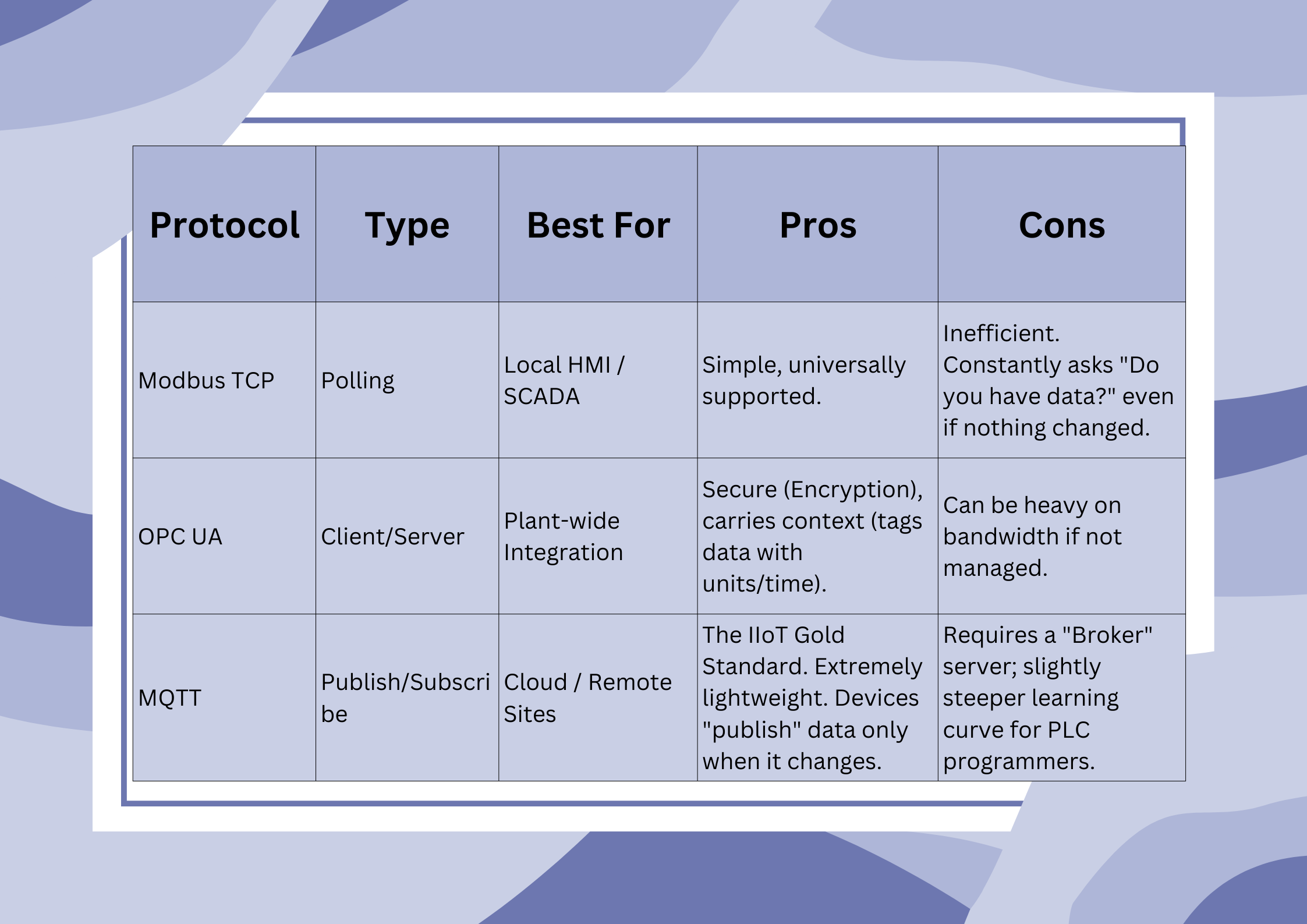

Level 3: The Transport – Communication Protocols

This is the language your system uses to talk to the server or cloud. Selecting the wrong protocol is the #1 cause of network congestion.

Selection Rule of Thumb:

Inside the machine (Real-time control) → Use Profinet / EtherCAT.

Machine to Plant Server (SCADA) → Use OPC UA.

Plant to Cloud / Remote Dashboard → Use MQTT.

Level 4: The Destination – On-Premise vs. Cloud

Where does the data go?

On-Premise Server (Local)

Setup: A physical server rack sitting in your IT room.

Best for: Companies with strict data privacy policies (e.g., Defense, Pharma) or unreliable internet connections.

Advance Engineers Service: We design SCADA systems with local Historians that give you 100% control over your data without a monthly subscription.

Cloud Dashboards (AWS / Azure / Proprietary)

Setup: Data is sent securely over the internet to a cloud platform.

Best for: Multi-site operations. If you have a plant in Mohali and another in Gujarat, the Cloud allows the CEO to view both on a single dashboard on their phone.

Selection: Look for platforms that support “Store and Forward.” If the internet cuts out, the local gateway buffers the data and uploads it automatically when the connection is restored.

Summary Checklist: How to Choose?

When Advance Engineers consults on an IIoT project, we ask these four questions to determine the system “Level”:

Latency: Do you need to know about the data in milliseconds (Motion Control) or minutes (Tank Level)?

Milliseconds = Edge Computing.

Minutes = Cloud Gateway.

Volume: Are we tracking 50 tags or 5,000 tags?

High volume requires MQTT to prevent network crashes.

Environment: Is the hardware going into an air-conditioned IT cabinet or a dusty foundry floor?

Foundry = IP67 Ruggedized Gateways.

Security: Will the IT department allow this device on the corporate network?

If yes, ensure the device supports SSL/TLS encryption (HTTPS).

The Advance Engineers Advantage

Selecting an IIoT system isn’t just about buying a gateway; it’s about architecture. We help you bridge the gap between OT (Operational Technology) and IT (Information Technology). Whether you need a simple IO-Link upgrade for better diagnostics or a full multi-plant MQTT dashboard, we engineer the solution that fits your reality.

Ready to digitize your factory? Let’s start small, scale fast, and measure everything. Contact Advance Engineers today.