Precision Inventory Management for Liquids, Solids & Gases

From Water Reservoirs to High-Pressure LPG—Measure Without Contact

Whether you're monitoring atmospheric tanks or pressurized vessels, we deliver level measurement solutions that are accurate, safe, and reliable. From 80GHz Radar to revolutionary non-invasive sensors—we match technology to your application.

✓ Correct Selection | ✓ Safety First | ✓ Lifecycle Support

The Game Changer: Non-Invasive Ultrasonic Level Measurement

Powered by Roto Technology Partnership

Revolutionary External Mounting Technology

Imagine measuring level in pressurized LPG bullets, chlorine tanks, or acid vessels—without ever drilling a hole. Our non-invasive ultrasonic sensors bond to the outside of the tank wall, eliminating safety risks and installation downtime.

- Zero Break-In: Sensor attaches externally. No welding, no drilling, no process shutdown required

- Maximum Safety: Perfect for LPG, Chlorine, Ammonia, Hydrogen, and corrosive acids—no risk of leakage

- Pressurized Vessels: Ideal for horizontal bullets, spheres, and high-pressure storage tanks

- Retrofit Friendly: Add level measurement to existing tanks without modifications

- Explosion-Proof: ATEX/IECEx certified for hazardous area installations

Accuracy & Application Engineering

Correct Selection

We choose between Radar, Ultrasonic, or Hydrostatic based on your specific conditions—foam, vapor pressure, dielectric constant, temperature, and tank geometry.

After-Sales Support

Local calibration, commissioning assistance, and troubleshooting support. We don't disappear after delivery—we stay with you throughout the lifecycle.

Millimeter Precision

±1mm accuracy for custody transfer applications and pharmaceutical batching systems. NABL-traceable calibration certificates provided.

We Match Technology to Application—Not the Other Way Around

Every tank is different. Foam, turbulence, vapor, temperature—these factors determine which sensor will work reliably. Our application engineers analyze your process before recommending a solution.

Engineering first. Products second. Your success always.Proven Solutions Across Critical Industries

⚡ LPG & Pressurized Gas Storage

Measuring level in pressurized tanks has always been challenging—until now. Our non-invasive Roto sensors make it safe and simple:

- Non-Invasive Mounting: External sensor bonded to tank shell—no penetration required

- LPG Bullets & Spheres: Horizontal and vertical pressure vessels up to 100 bar

- Hazardous Area Approved: ATEX Zone 1 & 2, IECEx certified for explosive atmospheres

- Chlorine & Ammonia Safe: No material compatibility issues—sensor never contacts the fluid

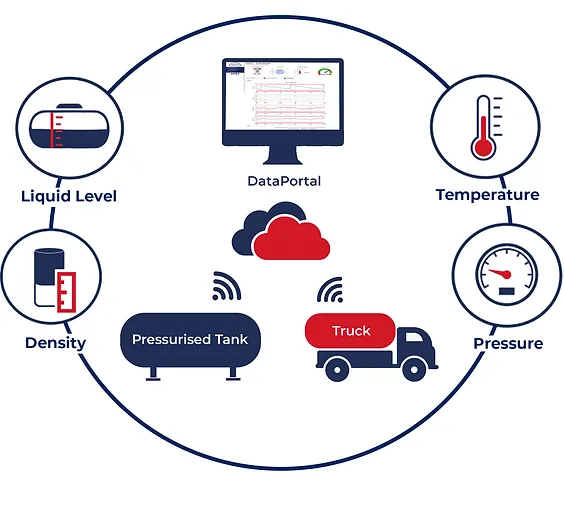

- Real-Time Inventory: 4-20mA, HART, Modbus output for SCADA integration

Typical Applications: LPG storage terminals, propane distribution, chlorine filling stations, ammonia tanks, hydrogen storage

Get LPG Tank Solution Quote

💧 Smart City & Water Management

IoT-enabled level sensors transform water infrastructure into intelligent networks:

- Remote Monitoring: Battery-powered ultrasonic sensors with LoRa/NB-IoT connectivity

- Reservoir & Tank Monitoring: 80GHz FMCW radar for large water storage tanks

- STP & WTP Level Control: Submersible hydrostatic sensors for wastewater treatment

- Cloud Dashboards: Real-time visualization, alerts, and historical trend analysis

- Leak Detection: Abnormal level change detection for distribution networks

Typical Applications: Overhead tanks, underground reservoirs, pumping stations, sewage treatment plants, water distribution networks

Explore Smart Water Solutions

🍽️ Food & Pharma (Batching & Dosing)

Hygienic level measurement for precise recipe management and regulatory compliance:

- Sanitary Radar Sensors: 3A certified, hygienic fittings (tri-clamp, DIN 11851)

- Batching Automation: High-precision level control for ingredient mixing and dosing

- CIP/SIP Compatible: Withstands high-temperature cleaning and sterilization cycles

- Non-Contact Measurement: No moving parts, no contamination risk, easy validation

- FDA Compliance: Material certificates, validation documentation, IQ/OQ/PQ support

Typical Applications: Mixing vessels, buffer preparation tanks, fermentation reactors, dosing systems, formulation tanks

Request Hygienic Sensor Quote

⛽ Oil & Gas Custody Transfer

Fiscal inventory management requires the highest accuracy and legal metrology compliance:

- Servo Tank Gauges: ±1mm accuracy for large atmospheric storage tanks

- Guided Wave Radar: Reliable measurement in crude oil, diesel, and fuel tanks

- Legal Metrology Approved: Weights & Measures certification for custody transfer

- Tank Farm Management: Automated inventory reporting, volume calculation, overfill prevention

- ATEX/IECEx Zone 0: Explosion-proof designs for intrinsically safe installations

Typical Applications: Crude oil tanks, refined product storage, aviation fuel depots, terminal automation, pipeline metering stations

Get Custody Transfer Solution

Download the Level Sensor Selection Matrix

Radar vs. Ultrasonic? Invasive vs. Non-Invasive? Guided Wave or Free Space? Download our comprehensive selection guide to choose the right sensor technology based on your fluid properties, tank geometry, and process conditions.

Your FREE Selection Matrix Includes:

- Technology Comparison Chart (Radar, Ultrasonic, Hydrostatic, Capacitance, Guided Wave)

- Application Suitability Guide (Liquids, Slurries, Powders, Aggressive Media)

- Non-Invasive vs. Invasive Installation Decision Tree

- Accuracy Specifications by Technology Type

- Tank Geometry Considerations (Vertical, Horizontal, Spherical)

- Cost-Benefit Analysis & ROI Calculator

No registration required. Instant PDF download. Trusted by 800+ tank operators.

Ready to Solve Your Tank Level Measurement Challenge?

Share your tank specifications with us—fluid type, tank dimensions, pressure rating, temperature range. Our application engineers will recommend the optimal sensor technology with detailed specifications and pricing.

Request Technical Consultation 📞 Call Now: +91-8427001018Serving industries across India: LPG & Gas | Water Utilities | Oil & Gas | Food & Beverage | Chemical | Pharma