How Manufacturing Plants Can Reduce Fuel Consumption, Improve Combustion Efficiency, and Meet Sustainability Goals

AE-Flux™ Fuel Optimizer: How Manufacturing Plants Can Reduce Fuel Consumption, Improve Combustion Efficiency, and Achieve Sustainability Goals Without Changing Fuel or Operations

By Advance Engineers | Energy • Efficiency • Automation

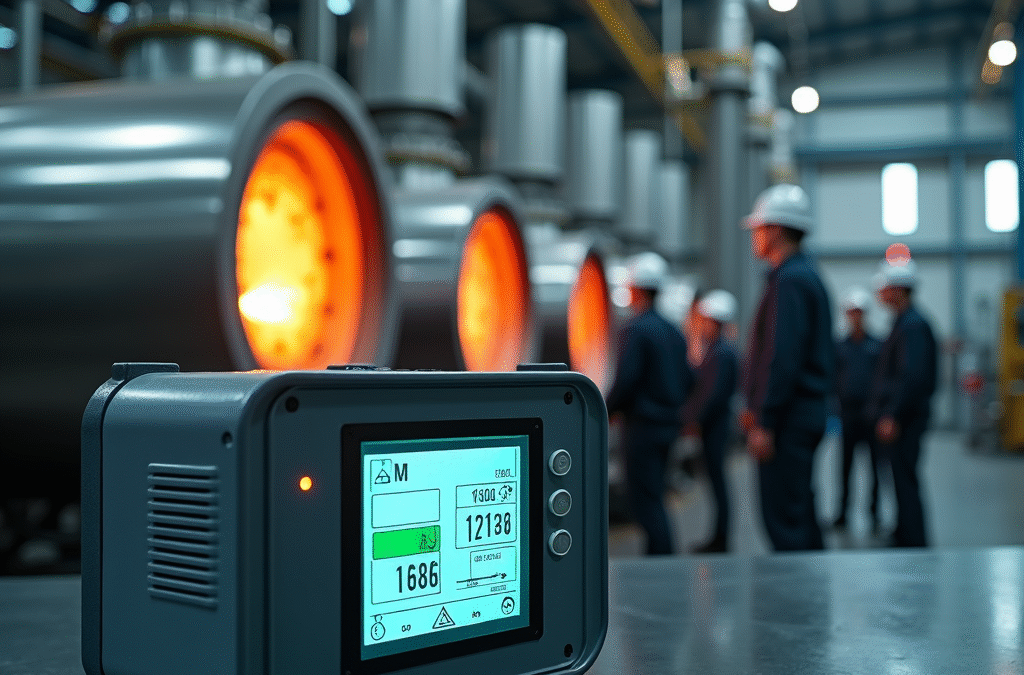

Across manufacturing industries, fuel continues to remain one of the largest and most sensitive operating expenses. Whether it is boilers, burners, thermic fluid heaters, furnaces, or diesel generator sets, fuel efficiency directly impacts profitability, compliance, and long-term sustainability.

Yet, despite investments in modern equipment, automation systems, and monitoring tools, most manufacturing plants continue to lose 5–15% of fuel energy every single day. This loss is rarely visible on dashboards, but it quietly erodes margins, increases emissions, and shortens equipment life.

This article explains why this happens, why conventional solutions often fall short, and how AE-Flux™ Fuel Optimizer helps manufacturing plants unlock efficiency already hidden in their fuel.

The Real Cost of Fuel Inefficiency in Manufacturing

Fuel inefficiency is rarely treated as a strategic issue. In many plants, it is accepted as “normal operating loss.” However, when viewed through an operational and financial lens, the numbers tell a different story.

- Fuel typically accounts for 15–40% of total operating cost

- A 1% inefficiency can translate into lakhs or crores annually

- Rising fuel prices magnify even small losses

- Emission norms and ESG reporting are becoming stricter

Efficiency Managers, Utility Heads, and Plant Owners today face a dual challenge:

Reduce fuel cost AND reduce emissions — without disrupting production.

This is precisely where traditional approaches begin to struggle.

Why Fuel Does Not Burn Completely (The Science Explained Simply)

Hydrocarbon fuels such as Diesel, Furnace Oil (FO), LDO, LPG, PNG, CNG, and Natural Gas do not exist as isolated molecules. They naturally form molecular clusters due to intermolecular forces known as van der Waals forces.

These clusters create multiple combustion problems:

- Oxygen cannot penetrate the inner molecules

- Fuel remains partially unburnt

- Carbon residue forms inside equipment

- Heat transfer efficiency drops

Additionally, as fuel flows through pipelines, friction causes electrostatic charging. Fuel and oxygen often carry similar electrical charges, leading to repulsion instead of attraction during combustion.

The result is incomplete combustion — regardless of how good the burner or engine is.

Why Fuel Additives and Frequent Tuning Are Not Long-Term Solutions

Many manufacturing plants attempt to improve combustion efficiency through:

- Chemical fuel additives

- Frequent burner tuning

- Higher excess air

- Manual operator interventions

While these methods may show short-term improvements, they introduce new challenges:

- Recurring cost

- Operator dependency

- Inconsistent results

- No fundamental change in fuel behavior

The root problem — fuel molecular structure — remains unchanged.

Introducing AE-Flux™ Fuel Optimizer

AE-Flux™ Fuel Optimizer is a non-chemical, inline fuel conditioning solution engineered by Advance Engineers to improve combustion efficiency using Magneto-Hydrodynamic principles.

AE-Flux™ works without:

- Chemicals or additives

- External electrical power

- Pipe cutting or shutdown

- Moving parts or maintenance

Nothing is added to the fuel. Nothing is removed from the fuel. The fuel is simply optimized to burn better.

How AE-Flux™ Works: Magneto-Hydrodynamic Fuel Optimization

Step 1: Magnetic Flux Interaction

As fuel flows through the pipeline section where AE-Flux™ is installed, it is subjected to a precisely focused magnetic field.

Step 2: Hydrocarbon De-Clustering

The magnetic field weakens intermolecular attraction, breaking large hydrocarbon clusters into smaller, more active molecules.

Step 3: Improved Oxygen Bonding

Smaller fuel molecules provide higher surface area for oxygen bonding, resulting in more complete combustion.

Step 4: Cleaner and Hotter Combustion

The optimized fuel burns more efficiently, producing higher usable heat with lower excess air.

Applications of AE-Flux™ Fuel Optimizer

AE-Flux™ is used across a wide range of industrial applications:

- Industrial boilers

- Burners and furnaces

- Thermic fluid heaters

- Diesel generator sets

- IC engines

- Gas turbines

Supported Fuels

- Diesel

- Furnace Oil (FO)

- LDO

- LPG

- PNG / CNG

- Natural Gas

Each AE-Flux™ unit is engineered based on fuel type, pipe size, flow rate, and operating temperature.

Real, Measurable Benefits for Manufacturing Plants

1. Fuel Savings

Most plants observe 5–10% reduction in fuel consumption after stabilization.

2. Reduced Carbon Deposits

Cleaner combustion reduces soot formation, improves heat transfer, and lowers maintenance frequency.

3. Lower Emissions

Reduction in CO, unburnt hydrocarbons, and smoke density supports pollution control compliance and ESG goals.

4. Improved Equipment Life

Lower fouling and stable combustion reduce thermal stress and extend asset life.

Indicative Case Examples

Textile Boiler – North India

Fuel: Furnace Oil

Fuel Saving: ~8.5%

Payback Period: ~7 months

Pharmaceutical DG Set – Western India

Fuel: Diesel

Fuel Saving: ~6.8%

Emission Reduction: ~25–30%

Food Processing Plant – Gas System

Fuel: PNG

Thermal Efficiency Improvement: ~9%

Why Small Percentages Deliver Big Financial Impact

If a plant spends ₹3 crore annually on fuel, a 7% reduction means:

- ₹21 lakh saved every year

- Pure bottom-line improvement

- No operational disruption

This is why energy efficiency is one of the fastest-return investments in manufacturing.

Environmental and ESG Impact

Fuel savings automatically translate into lower carbon emissions.

For diesel systems:

1 liter diesel ≈ 2.68 kg CO₂

Medium-sized plants can reduce 50–100+ tons of CO₂ annually, supporting:

- ESG disclosures

- Customer audits

- ISO 50001 compliance

Installation, Warranty, and Product Life

- Installation: Online, clamp-on, no shutdown

- Warranty: 2 years from date of installation

- Product Life: Unlimited if not mechanically damaged

Who Should Evaluate AE-Flux™

- Efficiency Managers

- Sustainability & ESG Heads

- Utility Managers

- Operations Managers

- Manufacturing Plant Owners

If fuel is a major cost driver in your plant, AE-Flux™ deserves evaluation.

Why Advance Engineers

Advance Engineers specializes in energy efficiency, industrial automation, and process optimization.

Our focus is not selling hardware — it is delivering measurable, verifiable outcomes.

Take the Next Step

Instead of assumptions, start with numbers.

👉 Visit the AE-Flux™ Landing Page

📲 WhatsApp Now for a Quick Technical Discussion

Energy saved is energy earned — and most plants already have savings hidden in their fuel.

![[Artistly Design] 01992d57-6f83-7241-b9da-cfe58b91bb01 Oxygen Analyser](https://advance-engineers.com/wp-content/uploads/2025/09/Artistly-Design-01992d57-6f83-7241-b9da-cfe58b91bb01.png)

![[Artistly Design] 01992d59-7862-73d8-8a51-a7fe4b1c3091 emissions](https://advance-engineers.com/wp-content/uploads/2025/09/Artistly-Design-01992d59-7862-73d8-8a51-a7fe4b1c3091.png)