Endotoxin Risks

The Invisible Siege on Vaccine Safety: Groundwater Contamination, Endotoxin Risks, and the Paradigm Shift to Atmospheric Water

ntroduction: The Criticality of the First Ingredient

In the ultra-high-stakes world of vaccine manufacturing, there is one raw material that surpasses all others in volume and critical importance: Water. It is the universal solvent, the cleaning agent, the steam source, and, most critically, the primary component of the final injectable product.

For biopharmaceutical engineers and facility directors, water quality isn’t just a spec sheet parameter; it is the bedrock of patient safety and regulatory compliance. Achieving Water for Injection (WFI) standards is a relentless battle against thermodynamics, chemistry, and microbiology.

For decades, the industry has relied on a seemingly infinite resource: groundwater. We drill, we pump, and then we build massive, energy-hungry cathedrals of filtration to torture that ground water into purity.

But the ground beneath our feet is changing. Aquifers are becoming stressed, depleted, and increasingly, a sink for the chemical and biological detritus of modern civilization. For facilities manufacturing life-saving vaccines, reliance on groundwater is no longer just an engineering challenge; it is an escalating risk management crisis.

This article takes a hard, technical look at the specific dangers lurking in groundwater—with an urgent emphasis on the difficult-to-destroy endotoxins that threaten vaccine batches. We will analyze the hidden economic and environmental costs of traditional purification and introduce the necessary paradigm shift: severing the connection to the ground and sourcing water from the cleanest aquifer on earth— the atmosphere.

Section 1: The Crisis Below – The Escalating Fragility of Groundwater Source

Groundwater was once considered a pristine source, naturally filtered by layers of soil and rock. That assumption is now dangerously outdated.

As global populations swell and industrial activity intensifies, subterranean water sources are under siege from two directions: depletion and contamination.

1.1 The Concentration Effect of Depletion

Many pharmaceutical hubs are located in water-stressed regions. As aquifers are over-drafted for municipal, agricultural, and industrial use, water tables drop. This depletion doesn’t just mean there is less water; it means the remaining water is often of poorer quality.

As water levels fall, concentrations of naturally occurring minerals (hardness, silica, arsenic) increase. Deeper wells often tap into ancient, brackish water, causing total dissolved solids (TDS) levels to spike unpredictably. A sudden doubling of feedwater TDS can overwhelm pretreatment reverse osmosis (RO) systems, leading to breakthrough and downstream contamination of polishing steps like Electrodeionization (EDI) or distillation units.

1.2 The Anthropogenic Cocktail

Far more concerning than natural minerals is the anthropogenic fingerprint on groundwater. Everything we release on the surface eventually migrates downward.

Agricultural Runoff: Nitrates, phosphates, and persistent pesticides seep into shallow aquifers used by many industrial parks.

Industrial Solvents: Trace amounts of volatile organic compounds (VOCs) and “forever chemicals” like PFAS (per- and polyfluoroalkyl substances) are increasingly being detected in groundwater globally. These compounds are notoriously difficult to remove and require expensive, high-maintenance activated carbon pre-treatment, which itself becomes a breeding ground for bacteria.

Emerging Contaminants: Pharmaceuticals, hormones, and personal care products flushed down drains are bypassing municipal treatment and entering the groundwater cycle.

For a standard manufacturing plant, these are headaches. For a vaccine facility requiring sterile WFI, they are potential catastrophes.

Section 2: The Stealth Threat in Pharma – Pathogens and the Endotoxin Nightmare

The primary focus of pharmaceutical water treatment is microbiology. While chemical purity is essential, biological contamination is immediate and deadly in an injectable product.

When sourced from groundwater, the bio-burden load is highly variable and often spikes after heavy rains or seismic activity disturbs the aquifer. While traditional pre-treatment aims to kill living bacteria, it often exacerbates the darker, more insidious problem: endotoxins.

2.1 The Difference Between Living and Dead Threats

Most facility engineers are comfortable dealing with viable bacteria (bioburden). You sanitize the loop, use UV lamps, and maintain continuous turbulent flow.

The greater challenge in vaccine manufacturing is Pyrogens, specifically Bacterial Endotoxins.

Endotoxins are lipopolysaccharides (LPS) that form the outer cell wall of Gram-negative bacteria (like E. coli, Pseudomonas, etc.). These bacteria thrive in groundwater, soil, and notoriously, in the pre-treatment stages of water systems (like carbon filters and softeners).

Here is the critical distinction: Endotoxins are not alive. They are the debris left behind when bacteria die or multiply.

Why Endotoxins are the Engineer’s Nightmare:

Heat Stability: Unlike living bacteria, you cannot simply boil endotoxins away. They remain stable at standard autoclaving temperatures (121°C). Destroying them via heat requires depyrogenation temperatures exceeding 250°C for extended periods—an incredibly energy-intensive process feasible only for glassware, not for bulk water storage.

Size and Filtration Evasion: Endotoxin molecules can aggregate into large micelles, but individual units are extremely small (down to 10,000 Daltons). They can pass through standard 0.2-micron sterilizing grade filters used to catch live bacteria.

The Consequences in Vaccines: If endotoxins enter an injectable vaccine, they trigger a severe, sometimes fatal, immune response in the patient—fever, shock, and organ failure. This is a “pyrogenic response.”

2.2 The Groundwater Connection to Endotoxin Spikes

Groundwater is naturally rich in Gram-negative bacteria. When an industrial facility pumps this water and subjects it to chlorination or other biocidal treatments at the intake, they successfully kill the bacteria.

However, in killing millions of bacteria simultaneously, the treatment process causes massive cell lysis, releasing a sudden, concentrated “bloom” of free endotoxins into the feedwater.

Traditional WFI generation systems (like vapor compression distillation or multi-effect stills) are designed to remove endotoxins through phase change. However, they are rated for a certain log-reduction. If the incoming feedwater from a contaminated groundwater source has an unprecedented spike in endotoxin load, it can challenge the distillation units to their breaking point.

Furthermore, any breach in pre-treatment RO membranes, or trace contamination in storage tanks prior to distillation, creates a persistent endotoxin issue that is incredibly difficult to trace and eradicate.

A vaccine batch testing positive for endotoxins above the USP limit is an immediate write-off. The financial loss is in the millions; the reputational damage is incalculable; the risk to patient supply chains is unacceptable.

Section 3: The Unsustainable Economics of Purifying Poison

To turn increasingly contaminated groundwater into WFI, facilities are forced to build higher, more complex defensive walls. The total cost of ownership (TCO) of these traditional water systems is skyrocketing, hidden in energy bills, maintenance logs, and waste hauling manifests.

3.1 The Energy Penalty

The thermodynamics of purification are brutal.

Distillation is King, but costly: The gold standard for WFI is distillation because it reliably separates water from non-volatiles like endotoxins. However, boiling thousands of liters of water an hour requires enormous amounts of steam, usually generated by natural gas boilers. It is often the single largest energy consumer in a pharma facility.

High-Pressure Pumping: Before distillation, groundwater must go through RO. High TDS groundwater requires higher pressure pumps to overcome osmotic pressure, driving up electricity usage significantly.

3.2 The Maintenance and Chemical Treadmill

A fluctuating groundwater source means constant tweaking of the pre-treatment train.

Chemical Reliance: To protect RO membranes from scaling due to groundwater hardness, facilities consume vast quantities of salt for softeners or anti-scalant chemicals. To combat bio-growth, various biocides are used. To remove chlorine before the RO, sodium metabisulfite is injected. This is a massive chemical procurement and storage undertaking.

Membrane Fouling and Replacement: Groundwater rich in organics and colloids fouls RO membranes rapidly. This necessitates frequent Clean-In-Place (CIP) cycles using aggressive acids and caustics, which shortens membrane life and leads to expensive replacements and production downtime.

3.3 The Environmental Burden: The Reject Water Problem

Perhaps the most overlooked aspect of traditional water treatment is its inefficiency. To make pure water, you must waste water.

For every gallon of purified water produced via a standard RO setup operating on challenged groundwater, roughly 25% to 40% of the feed water becomes “reject” or concentrate stream.

This isn’t just water; it’s hazardous brine. It contains 100% of the contaminants removed from the product water, concentrated into a smaller volume, plus all the added anti-scalants and treatment chemicals.

High TDS Pollution: Discharging this high-salinity waste into municipal sewers is increasingly regulated and expensive. In some jurisdictions, it requires on-site evaporator crystallizers to achieve Zero Liquid Discharge (ZLD), adding another massive layer of CAPEX and OPEX.

The Water Footprint: In an era of water scarcity, wasting 40% of the water you pump just to clean the other 60% is environmentally indefensible.

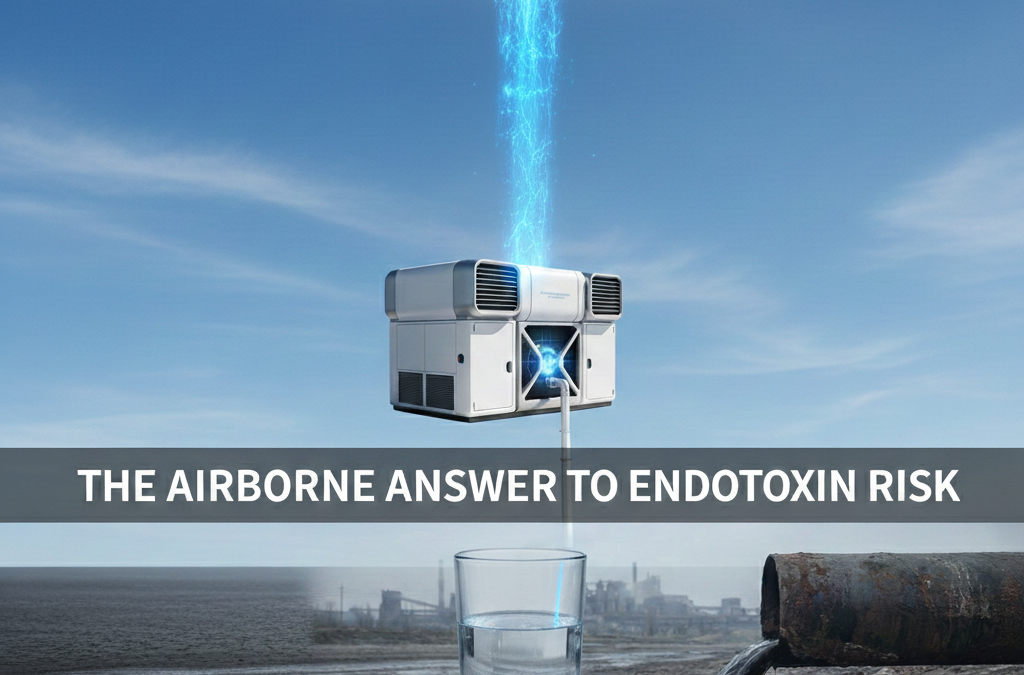

Section 4: The Paradigm Shift – Atmospheric Water Generation (AWG)

If groundwater is becoming a reliability liability, what is the alternative?

The answer lies in changing the source entirely. The atmosphere contains an estimated 37.5 million billion gallons of water vapor. It is a replenishable, mobile aquifer that naturally bypasses terrestrial ground contamination.

At Advance Engineers, we are pioneering the integration of industrial-scale Atmospheric Water Generators (AWGs) into critical applications like vaccine manufacturing.

4.1 Bypassing the Ground: The Ultimate Pre-Treatment

An AWG is essentially a highly sophisticated dehumidifier optimized for water production. It pulls in ambient air, filters it to remove particulates, passes it over chilled coils to condense the vapor into liquid water, and then subjects that water to immediate purification.

By sourcing from the air, we eliminate the primary vectors of risk discussed above:

No Agricultural Runoff: Air doesn’t contain nitrates or pesticides in meaningful quantities.

No Subterranean Mineral Spikes: The water starts with very low TDS (essentially distilled by nature).

Dramatically Lower Bio-burden: While air contains bacteria, the load is vastly lower and less variable than groundwater sources, and significantly lower in Gram-negative bacteria that cause endotoxin issues.

4.2 AWG as the Ideal Feed for WFI Systems

We are not suggesting AWG product water is injectable straight from the machine. WFI requires rigorous, validated distillation or membrane processes defined by USP/EP pharmacopeias.

However, AWG water is the perfect feed water for those WFI stills.

By providing a consistent, low-TDS, low-endotoxin feed stream to a Vapor Compression Distiller, you achieve:

Reduced Energy Consumption: The distiller works less hard, reducing scaling and blowdown frequency.

Simplified Pre-treatment: You can potentially eliminate water softeners, massive carbon beds, and primary RO passes, shrinking the facility footprint and removing areas where bacteria breed.

Risk Mitigation: You remove the “spike variable.” You no longer have to worry about what a heavy rainfall event did to the aquifer five miles away. The input quality is stable.

Section 5: Sustainability and the Future of Our Generations

Adopting AWG technology is not just an engineering decision; it is a statement of corporate values.

Pharmaceutical companies have a dual obligation: to provide life-saving medicines today, and to ensure a habitable world for the patients of tomorrow.

Continuing to exploit stressed groundwater aquifers for industrial processes, while simultaneously polluting water systems with high-TDS reject streams, is antithetical to modern Environmental, Social, and Governance (ESG) goals.

By adopting Atmospheric Water Generation, a facility:

Decouples growth from local water stress: You become water-independent, ensuring business continuity even during droughts or municipal water crises.

Eliminates reject water pollution: AWG produces no brine discharge.

Demonstrates leadership: It signals a commitment to innovative, sustainable technologies that protect our shared natural resources.

This is about securing the future of manufacturing and fulfilling our moral obligation to leave a water-secure planet for the next generation.

The Final Call to Action

The risks of relying on groundwater for vaccine manufacturing are no longer theoretical; they are financial, operational, and ethical ticking time bombs. The threat of endotoxin contamination creates an unacceptable level of risk in an industry where safety is paramount.

The old ways of brute-forcing purity through massive chemical and energy expenditure are becoming obsolete.

Ideally, the purest final product should start with the purest raw material. Air is that material.

Advance Engineers is ready to help your facility assess the feasibility of industrial Atmospheric Water Generation. We can model the energy savings, the risk reduction, and the sustainability benefits of shifting your feedwater source from the ground to the sky.

Stop managing groundwater crises. Start generating pure water security.

Discover how AWG can revolutionize your critical utility strategy. Visit our detailed AWG solutions page to learn more:

![[Artistly Design] 01992d57-6f83-7241-b9da-cfe58b91bb01 Oxygen Analyser](https://advance-engineers.com/wp-content/uploads/2025/09/Artistly-Design-01992d57-6f83-7241-b9da-cfe58b91bb01.png)

![[Artistly Design] 01992d59-7862-73d8-8a51-a7fe4b1c3091 emissions](https://advance-engineers.com/wp-content/uploads/2025/09/Artistly-Design-01992d59-7862-73d8-8a51-a7fe4b1c3091.png)