Manual Labour vs Automated Future Can Indian Industry Afford to Wait?

Indian manufacturing stands at a decisive crossroads.

On one side is the familiar comfort of labour-driven production—people on shop floors, manual inspections, supervisor-dependent quality, overtime firefighting, and productivity that fluctuates with every shift change.

On the other side is an automated future—factories that run 24/7, deliver predictable quality, generate real-time data, and scale without chaos.

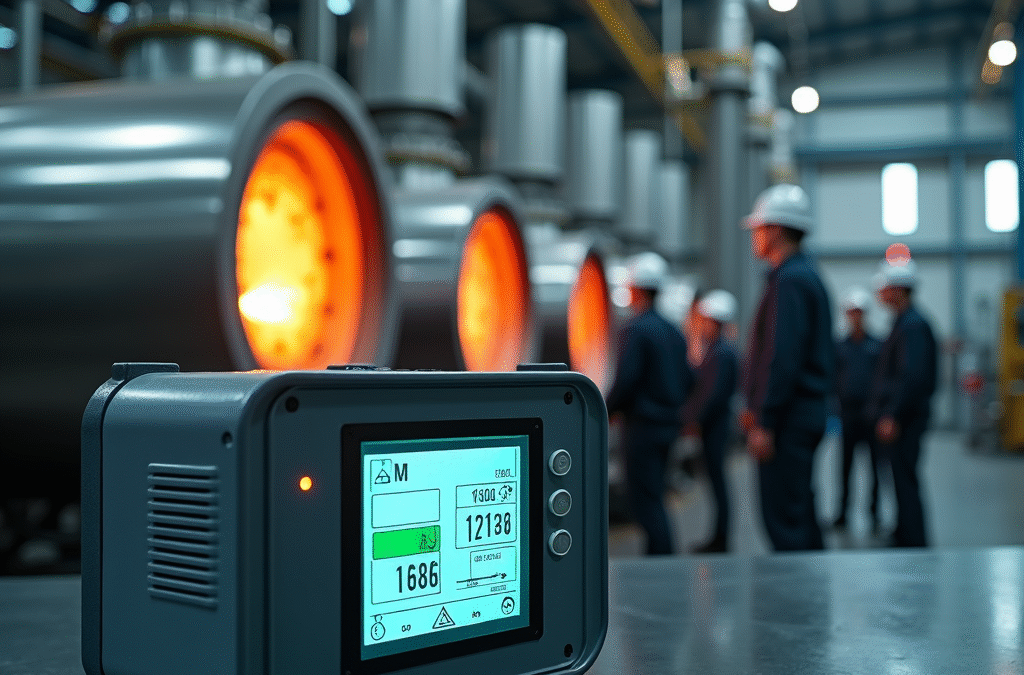

The image you see tells this story in a single frame:

Manual Labour vs Automated Future.

The question staring Indian industry in the face is no longer whether automation will happen.

The real question is:

Can Indian industry afford to wait any longer?

The Illusion of Cheap Labour

For decades, Indian manufacturing has leaned heavily on one advantage: low-cost labour.

It worked—until it didn’t.

Today, the so-called “cheap labour” model hides massive invisible costs:

❌ Quality rework and rejection losses

❌ Inconsistent output between shifts

❌ Supervisor dependency

❌ High attrition and retraining cycles

❌ Safety incidents and downtime

❌ Production planning uncertainty

What looks economical on paper becomes expensive on the balance sheet.

In many factories:

Output depends more on who is on the shift than on what system is running

Quality is inspected after defects are created

Maintenance is reactive, not predictive

This is not a labour problem.

This is a system design problem.

Automation Is Not About Replacing People

One of the biggest myths holding Indian industry back is fear.

“Automation will replace jobs.”

The truth is very different.

Automation replaces:

Repetition

Errors

Fatigue

Inconsistency

Automation upgrades human roles from:

Doing → Supervising

Fixing → Preventing

Guessing → Deciding with data

Globally competitive factories don’t remove people—they remove chaos.

The Rise of the Dark Factory

A “dark factory” is not science fiction.

It is a production facility capable of operating:

Without human presence

Without lighting

Without breaks

With zero compromise on quality

Robots don’t need:

Light

Air conditioning

Lunch breaks

Motivation speeches

They need:

Clear process design

Reliable automation architecture

Integrated control systems

Global manufacturers have already moved from:

Automation pilots → Automation platforms

Manual inspection → Inline quality intelligence

Standalone machines → Integrated digital factories

While many Indian plants are still debating feasibility studies, the world is already optimising version 2.0.

Why Indian Industry Is Still Hesitating

Despite having:

Strong engineers

Competitive capital costs

A massive domestic market

Automation adoption remains slow.

Why?

1. Short-Term Cost Thinking

Automation is seen as capex, not capability.

What’s ignored:

Cost of poor quality

Cost of lost reputation

Cost of missed scale opportunities

2. Fragmented Decision Making

Automation decisions are split across:

Production

Maintenance

Finance

IT

Result: no one owns the outcome.

3. Fear of Complexity

Many plants believe automation equals:

High risk

Long downtime

Vendor dependency

In reality, poorly planned automation fails—not automation itself.

The Execution Gap

The biggest difference between global leaders and laggards is execution speed.

Automation success is not about technology alone.

It’s about architecture and discipline.

Winning factories:

Design processes before automating

Build modular, scalable systems

Integrate quality into production—not inspection

Use data for decisions, not reports

Automation is not a machine purchase.

It is a manufacturing philosophy.

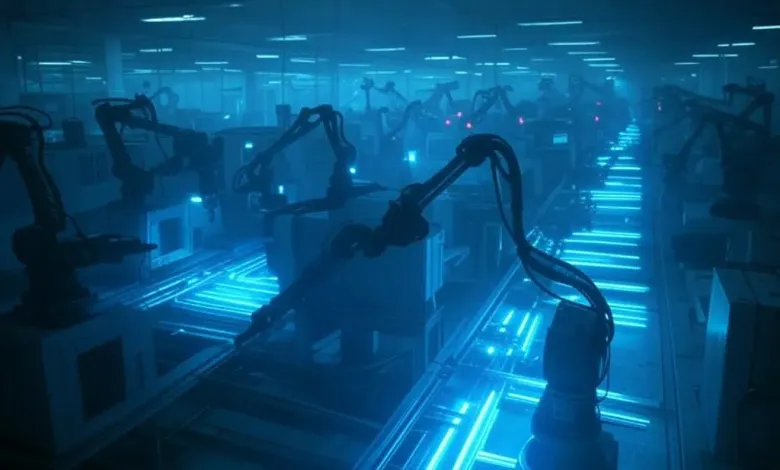

What the Future Factory Actually Looks Like

The future factory is not labour-free.

It is error-free and dependency-free.

Key characteristics:

🔹 Automation-First Design

Processes are designed assuming automation—not retrofitted later.

🔹 Predictable Quality

Quality is controlled by systems, not supervisors.

🔹 Data-Driven Operations

Every machine talks. Every deviation is visible.

🔹 Scalable Production

Adding volume does not add chaos.

🔹 Safer Work Environment

Humans move away from hazardous and repetitive tasks.

Where Automation Delivers Immediate ROI

Automation does not need to start with a “big bang”.

High-impact starting points:

Material handling and movement

Repetitive assembly operations

Inline inspection and testing

Energy monitoring and optimisation

Batch process control

Production data capture (OEE, downtime, rejects)

Most factories recover automation investments faster than expected—because hidden losses disappear.

The Indian Context: Why Now Is the Right Time

India is uniquely positioned right now:

Rising labour costs

Increasing quality expectations

Export-driven compliance requirements

Government focus on manufacturing excellence

Digital-native engineering talent

The question is not readiness.

The question is intent.

From Labour Advantage to Capability Advantage

The next decade will separate manufacturers into two categories:

1️⃣ Survivors

Low margins

High stress

Constant firefighting

2️⃣ Leaders

Predictable output

Consistent quality

Scalable growth

Global competitiveness

The difference will not be labour cost.

It will be system capability.

Automation Is a Leadership Decision

Automation is not a shop-floor project.

It is a boardroom decision.

Leaders must ask:

Do we want predictable growth or reactive survival?

Are we building a factory—or a system?

Are we optimising today—or designing for the next decade?

How Advance Engineers Helps Factories Transition

At Advance Engineers, we don’t sell machines.

We build automation roadmaps.

Our approach:

Understand your current process reality

Identify high-impact automation opportunities

Design scalable control and instrumentation architecture

Ensure safety, quality, and compliance

Deliver measurable ROI—not just installations

Automation done right is silent, stable, and scalable.

Final Thought

The future factory will not run on cheap labour.

It will run on intelligence, integration, and intent.

The longer automation is delayed, the wider the execution gap becomes.

The real risk today is not automation failure.

The real risk is standing still while the world moves ahead.

🚀 Call to Action: Free Automation Readiness Analysis

If you are a:

Plant Head

Factory Owner

Operations Leader

Manufacturing Decision Maker

👉 Book a FREE Automation Readiness & Opportunity Analysis for your factory

We will help you understand:

Where automation makes sense

What to automate first

Expected ROI and timeline

A practical, phased roadmap

🔗 Book your free analysis here:

![[Artistly Design] 01992d57-6f83-7241-b9da-cfe58b91bb01 Oxygen Analyser](https://advance-engineers.com/wp-content/uploads/2025/09/Artistly-Design-01992d57-6f83-7241-b9da-cfe58b91bb01.png)

![[Artistly Design] 01992d59-7862-73d8-8a51-a7fe4b1c3091 emissions](https://advance-engineers.com/wp-content/uploads/2025/09/Artistly-Design-01992d59-7862-73d8-8a51-a7fe4b1c3091.png)